Programmable digital hydraulic unit

From the union of hydraulic and digital electronics comes the Smart Power Unit Hydronit, the first compact programmable hydraulic power unit on the market. From the point of view of the range of hydraulic components, the SPUs share the same modularity concept (and most of the components) of the PPC series, thus offering the same flexibility.

Programmable digital hydraulic unit

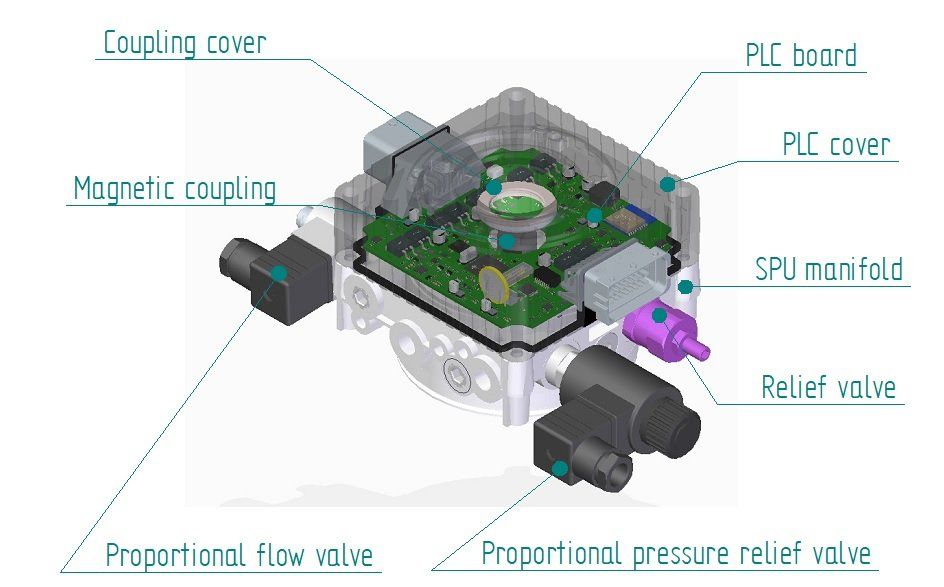

The Smart Power Unit is the first generation of programmable digital hydraulic power unit available on the market. The heart of the Smart Power Unit is the HPC (Hydraulic Process Controller): a mechatronic module that integrates sensors, electronics and hydraulics in a single device, programmable with the CodesysTM IEC61131-3 automation software.

Hydronit has developed the Smart Power Unit, the first compact intelligent hydraulic power unit in the world.

FEATURES

The heart of the SPU is the HPC (Hydraulic Process Controller): a programmable controller with SAFETY Architecture. It integrates I / O, sensors, redundant double core processors with SAFETY and output power features to directly drive proportional solenoid valves or on-off valves without the need for external relays.

The hydraulic process controller is integrated in the hydraulic unit and available in different executions: proportional control of pressure [P], flow rate [Q] or P / Q with optional Load Sensing [LS] functionality.

HYDRAULIC INTEGRATION

HPC is seamlessly integrated with the standard Hydronit PPC compact power supply range as it uses the same standard PPC components.

Typical hydraulic circuits can be made with redundant valves in order to create SAFE (SIL2) applications ready for Industry 4.0 and Smart Manufacturing.

INTERNATIONAL AWARDS

Hydronit, in direct competition with the best European companies, has been awarded with multiple certificates of excellence from the European Commission during the Horizon 2020 framework program for research and innovation and, starting from July 2017, co-financed as a highly innovative.

The Smart Power Unit is patented n ° WO 2017/162298 A1.

Questions and answers

Application sectors

Hydronit compact power units are used where space limits make it difficult to install a traditional centralized hydraulic unit, such as in vehicles, boats, small industrial machines. Distributed hydraulics, installed close to the actuator, enables cost and installation savings and offers redundancy in the event of a failure.