MOBILE SECTOR

The mobile sector includes applications involving hydraulic power packs with direct current power supply, generally from battery, at 12V, 24V or 48V

Hydronit offers diversified and specialized solutions for intensive applications, thanks to the optional forced cooling of the engine, such as the cleaning of long-distance roads and motorways.

The Smart Power Unit provides for complete control of the snow plow blade, without the need for additional management electronics, and connection via CAN-BUS with the vehicle.

To complete the hydraulic control unit for the snow plow blade, accessories such as touch screens and customizable keyboards are available.

DOWNLOAD the sheet

Hydraulic power packs for PLE Mobile elevating work platforms

The safety necessary for machines with man on board is guaranteed by the SIL2 certification of the SPU (Smart Power Unit Hydronit) hydraulic control unit, which can control the leveling of the basket, the stabilizers, the overload and the anti-tipping function.

Smart Power Unit for Forklifts

The Hydronit hydraulic unit is able to manage the ascent, descent and precise positioning of the forks proportionally. The programmable digital version SPU (Smart Power Unit) allows the complete control of the hydraulic and electrical parts in a safe way (SIL2) reducing the TCO (Total Cost of Ownership).

Power supply 12V, 24V and 48V and motors with forced ventilation for heavy use.

DOWNLOAD the sheet

The programmable digital hydraulic control unit SPU (Smart Power Unit) Hydronit is expressly programmed to manage the basket leveling function in a safe way (SIL2). The digital controller of the SPU directly reads the integrated 3-axis accelerometer and operates the coils of the proportional valves (PWM) avoiding the use of external electronics and sensors and thus reducing the TCO (Total Cost of Ownership).

12V, 24V and 48V DC power supply and motors with forced ventilation for heavy duty.

DOWNLOAD the sheet

The Hydronit hydraulic control unit controls the leveling of the lighting tower, but also of any other similar machine, by means of the stabilizers. The programmable digital version SPU (Smart Power Unit) can safely control self-leveling (SIL2) thanks to the digital controller that directly reads the integrated 3-axis accelerometer and operates the coils of the proportional valves (PWM) avoiding the use of electronics and external sensors and thus reducing the TCO (Total Cost of Ownership).

The same control unit controls the lifting and lowering of the tower with the lighting lamps.

DOWNLOAD the sheet

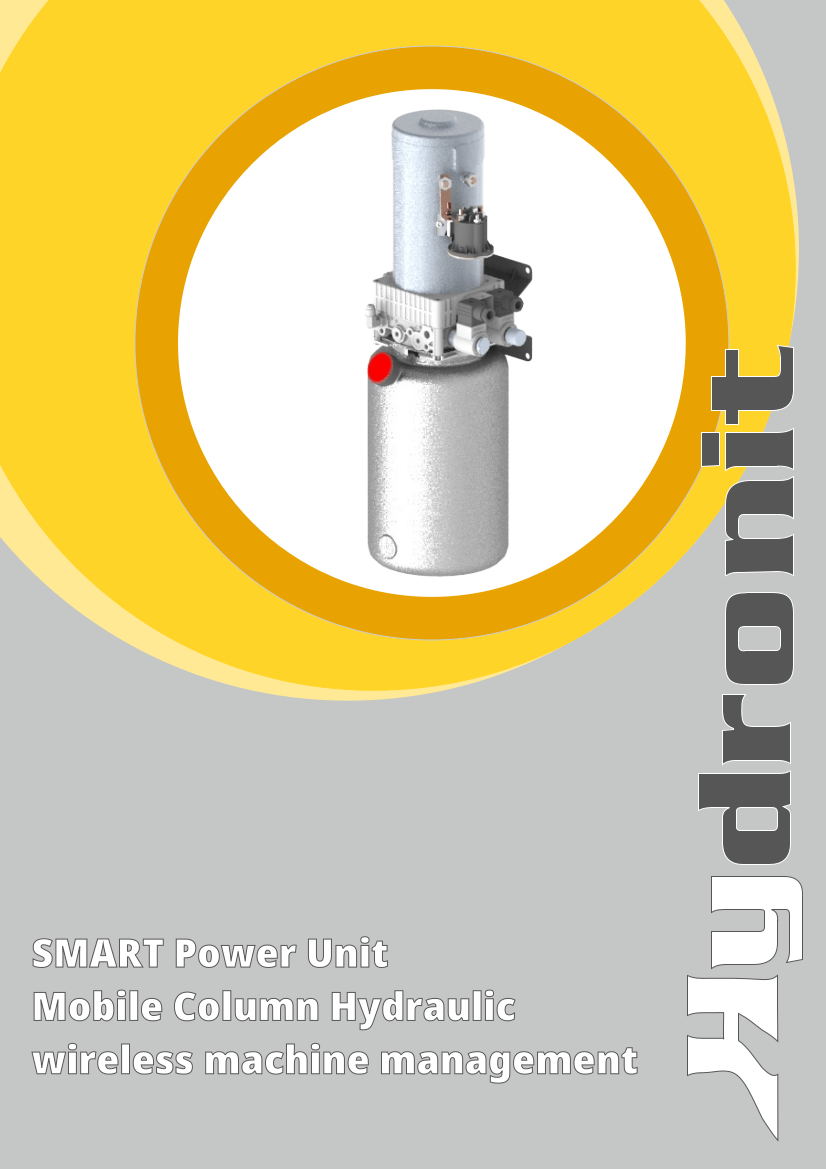

The Hydronit hydraulic unit controls and coordinates the synchronization between several lifts, up to 12, thanks to the wireless "STAR" connection. Variable loads are compensated by the leveling logic in a safe way (SIL2) thanks to the digital controller that directly reads the position and speed of the respective cylinders and operates the coils of the proportional (PWM) or on-off valves, avoiding the use of electronics and drivers and thus reducing the TCO (Total Cost of Ownership). 12, 24 and 48VDC direct current motors.