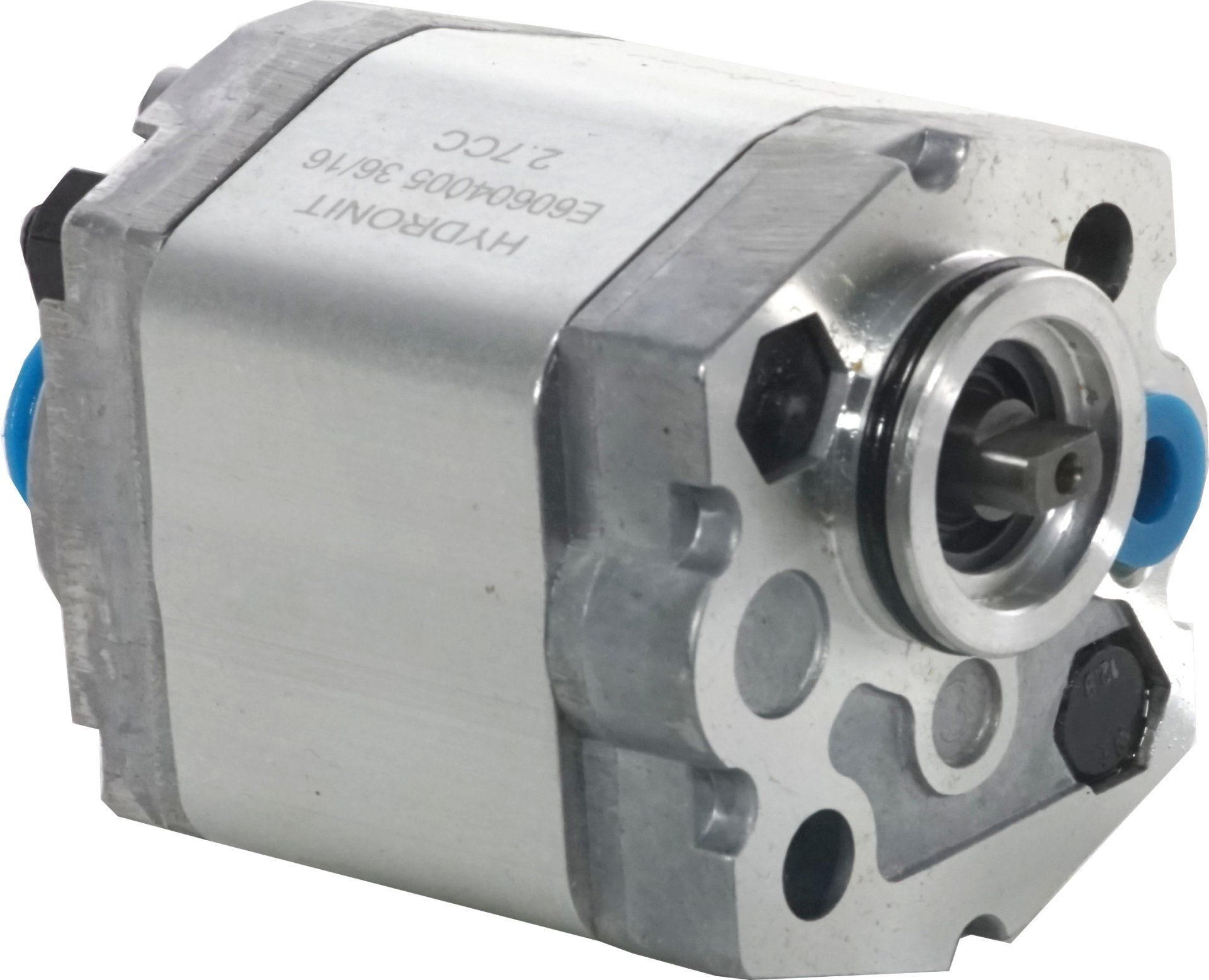

HYDRAULIC GEAR PUMPS

Gear pumps are a strategic component to define the volumetric and mechanical efficiency of a control unit, as well as to limit its noise.

Unlike many of our international competitors, all Hydronit pumps are equipped with backlash compensation for high pressure and high efficiency operation. This allows energy savings and avoids overheating of the fluid typical of fixed clearance pumps.

The displacements vary from 0.15 to 10 cc / rev. The rotation of the standard and hourly pumps (seen from the shaft side).

Other peculiar characteristics are:

- High pressure, up to 300 bar, with the availability of pumps up to 350bar for special executions.

- High volumetric and mechanical efficiency

- Low noise. Helical gear versions are available

- Reversible pumps available for bidirectional circuits

- Double pumps available, with HI-LO circuit

K series pumps also available as double pumps with or without HI-LO circuit integrated inside the pump itself.

Compact, pressure compensated, low noise and high efficiency G series pumps specifically designed for mini power plants.

H series pumps equipped with an oversized shaft and a higher number of teeth for high pressure applications.

R series pumps Bi-directional pumps with integrated suction check valves and two front outlets. To be mounted on SR central bodies.

S series pumps with helical gears, extremely quiet, low pulsation and high pressure.